perma

Well-known member

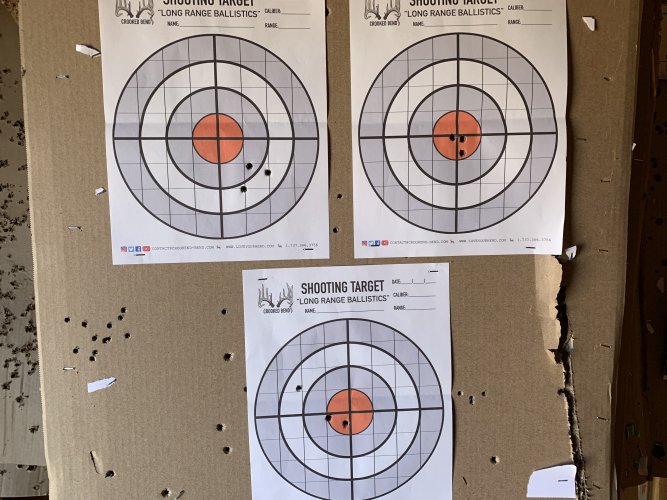

On the other hand, I think I found the issue. When I was loading a new set tonight, I found that the rim of the shell where the bullet seats seemed to be kind of rolled. I’m thinking the ribs on the Barnes are causing that, so maybe it’s loosening the bullet somehow when I seat it. If this doesn’t work out, I’m switching bullets.