Buy don’t build. I’m super handy and have built garages, barns, and a house. I’ve posted some of my metal fab in the other thread.

and you're probably not going to come out ahead on the money front...

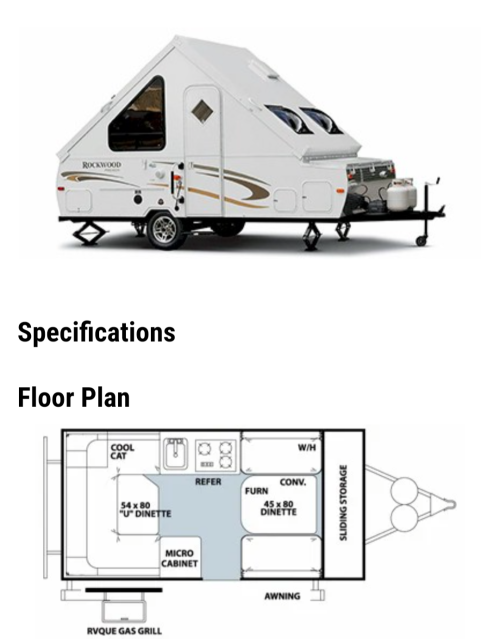

This is the primary consideration. It's a simple design with one of who knows how many Amazon sold roof tents framed onto the top and a cut out to enter from the floor level. Likely more riveting than welding aside from the actual steel frame and the general Aluminum body that would bolt to the steel trailer portion.

Seems a fun project - that said... half to three quarters the way through this size of a hobby project has me cussing and chasing fugg ups. My mind races on "improvements" such as four corner jacks to raise the upper half for standing room as it sure looks like a kneeling space only design - from the pics.

And then as LuketheDog shared - would I actually save $? I've built a couple flatbed trailers for friends, an 8x4x3 large single hay trailer hinged to scoop and auto winch to hoist the bale for routing as a farm trailer. Mostly I've stayed under budget - though nowhere near under budget if I accounted the time and PITA moments during the process, Haha!

3/4 says buy... 1/4 says fun. Thanks for the input thus far. much appreciated.

Surprisingly, this weighs 700#! It's a very interesting revamp of the "tear drop" style that, IMO is much more practical than that ridiculous tear drop design.