COElkChaser

Member

- Joined

- Oct 8, 2019

- Messages

- 58

Just starting out in the world of reloading, and got out to the range this week to test my first loads.

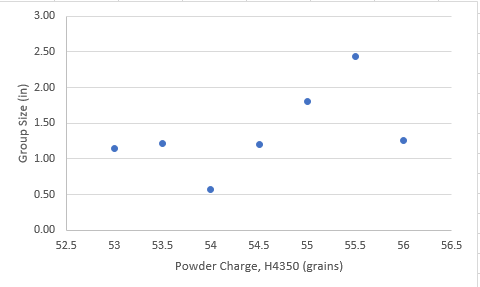

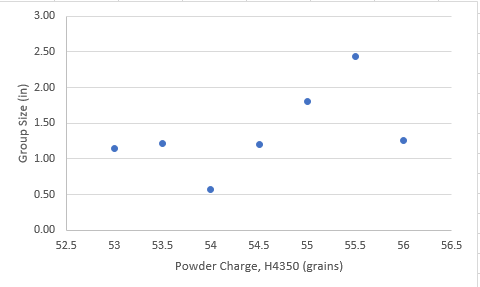

I'm shooting a 30-06, and I full-length sized once fired nosler brass. I loaded 168gr TTSX with H4350 from 53 - 56 gr with 0.5 gr increments. I made up 3x of each and measured group size at 100 yards.

There were no signs of excess pressure that I could see, but I did notice that closing the bolt was more difficult on some cartridges. Was my sizing die set up incorrectly?

What do you make of these groups? Makes sense to test out more of the 54gr I think, but I would like to explore higher powder weights as well. 58 gr seems pretty common and there weren't any issues at 56 gr so I may step up in more 0.5 gr steps. Any and all thoughts appreciated, thanks!

I'm shooting a 30-06, and I full-length sized once fired nosler brass. I loaded 168gr TTSX with H4350 from 53 - 56 gr with 0.5 gr increments. I made up 3x of each and measured group size at 100 yards.

There were no signs of excess pressure that I could see, but I did notice that closing the bolt was more difficult on some cartridges. Was my sizing die set up incorrectly?

What do you make of these groups? Makes sense to test out more of the 54gr I think, but I would like to explore higher powder weights as well. 58 gr seems pretty common and there weren't any issues at 56 gr so I may step up in more 0.5 gr steps. Any and all thoughts appreciated, thanks!