Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Metalworking Hunttalkers!

- Thread starter p_ham

- Start date

blueridge

Well-known member

Always impressed with your welding skills, Nathan. Respect.

np307

Well-known member

Appreciate it. I've still got plenty to learn but it's cool to do stuff that I know I wouldn't have been able to last year.Always impressed with your welding skills, Nathan. Respect.

np307

Well-known member

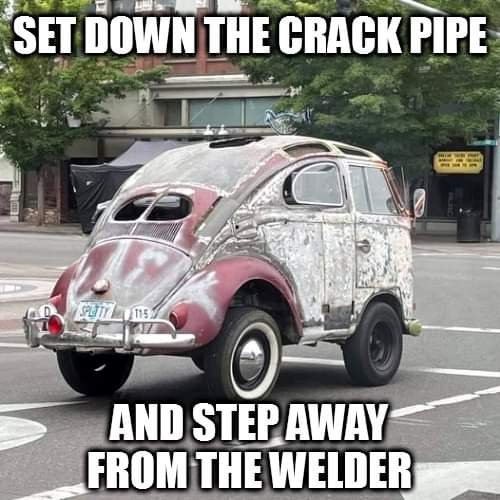

Here's a project, less the crack pipe... Haha! Pretty bad ass! I wouldn't cruise the streets in it BUT I would definitely take it out to the desert with a gremlin revamp project and race, smash, roll and make it a new quality target to shoot at... You know, giveth metals back to mother earth.

Just kidding. We'd torch them first... What? Clean up our garbage? Bah!

Just kidding. We'd torch them first... What? Clean up our garbage? Bah!

A few recent projects. Put a scale kit on the dry spreader, beefed up the plans with the angle iron welded to the box. Extended the wheels out on both AA bars so the wings will stay in the ground better. And put together a scoreboard frame for a local town. I need to get better at taking pics during the projects.

KB_

Well-known member

I know you said you had a boss, but is this a family business? Why dont you go out on your own, you clearly have the skillset.

np307

Well-known member

Not a family business, but my boss (the only other person in the business) is a friend that we go to church with. Several reasons to stay with how things are.I know you said you had a boss, but is this a family business? Why dont you go out on your own, you clearly have the skillset.

1) I really don't have the skillset to break out. I've made a lot of progress and am pretty confident in my ability as a welder, but there's a lot more that I need to learn and practice.

2) money. I don't have my own rig or shop. I don't have enough reserves to try to start up a business and deal with the long periods of time with no income.

3) time. I work 4 days a week and can take plenty of time off to hunt and fish. I'm W2 not 1099 so I have tax advantages that way.

4) goals. I enjoy welding, but I also am a pastor at heart. We are working on planting a church and while there'll still be plenty of years I'll have to work bivocationally, ultimately I don't plan to be doing it forever.

KB_

Well-known member

Not a family business, but my boss (the only other person in the business) is a friend that we go to church with. Several reasons to stay with how things are.

1) I really don't have the skillset to break out. I've made a lot of progress and am pretty confident in my ability as a welder, but there's a lot more that I need to learn and practice.

2) money. I don't have my own rig or shop. I don't have enough reserves to try to start up a business and deal with the long periods of time with no income.

3) time. I work 4 days a week and can take plenty of time off to hunt and fish. I'm W2 not 1099 so I have tax advantages that way.

4) goals. I enjoy welding, but I also am a pastor at heart. We are working on planting a church and while there'll still be plenty of years I'll have to work bivocationally, ultimately I don't plan to be doing it forever.

Yea that makes sense. I do a little fab work out of my garage, but only for friends and cash under the table. The tax and time situation makes running a business and working my normal day job as a desk sitter very difficult. Especially considering my wife works full time in the ER as well.

That must be nice to be able to work with your friends. Makes the daily grind and commute to work much easier to deal with, when the person you work with is a personal friend as well.

np307

Well-known member

Got a few days off so I decided to complete a project that I started last year. The plan for this bed was supposed to involve a lot of woodworking. I have all the wood sitting in the shed but I just don't have the time to mess with getting it all dimensioned and usable, so I decided to order some square tubing and use the plywood panels I already had cut for a nice contrast. Pretty straightforward design, it'll bolt onto a prefabbed frame.

np307

Well-known member

np307

Well-known member

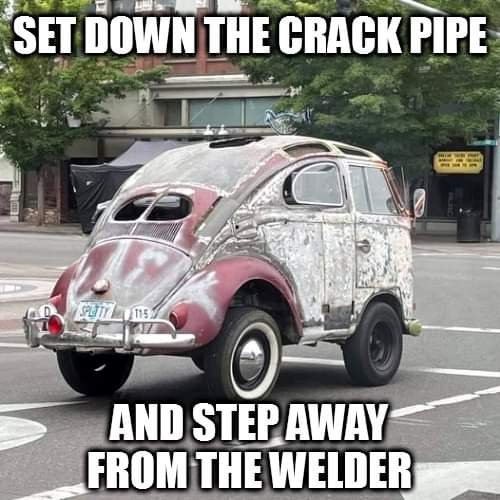

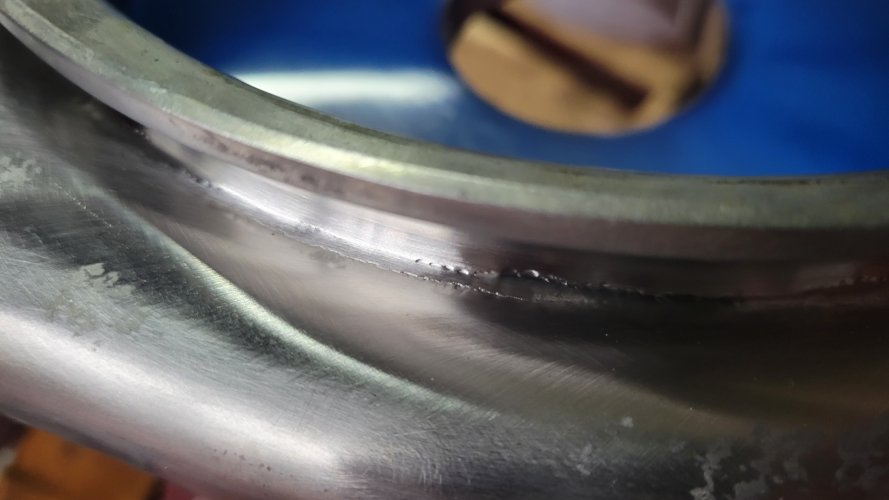

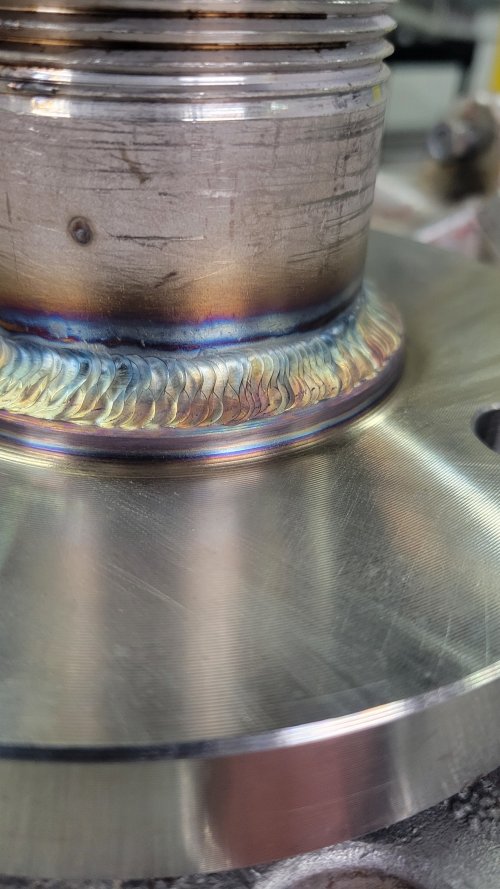

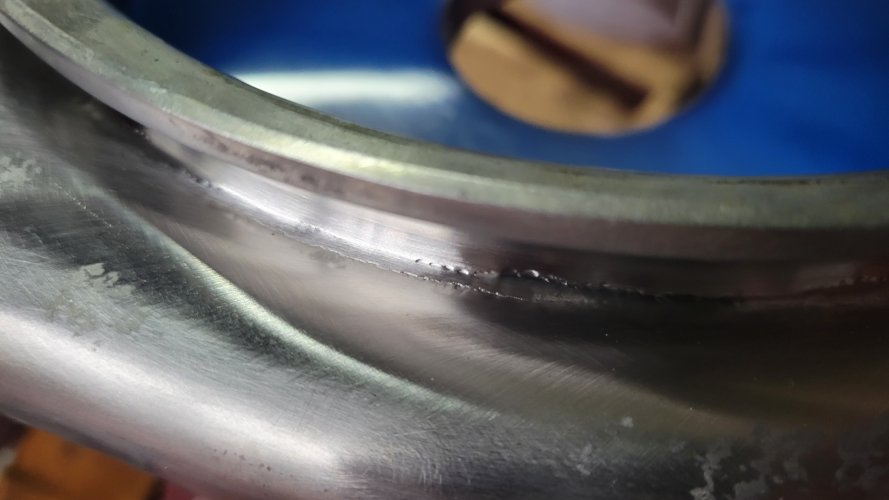

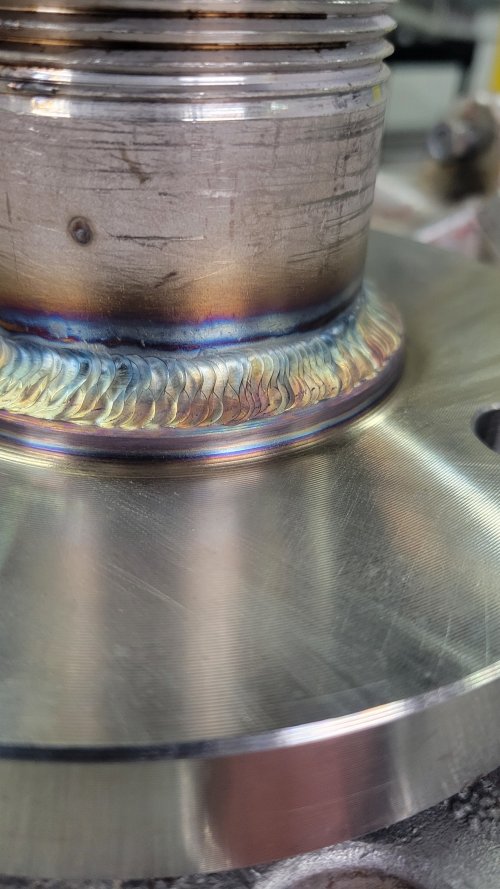

We've been slammed at work, projects at 5 different plants in the works. The main thing we've been working on is completely redoing the steam lines in a CIP room, all in stainless. This is a bunch of prefab so that hopefully we only have to shut the system down for a day to install and make a couple in-position welds. I also got handed a pump housing that had cracked in a previous repair, they have a new housing coming but they needed to be able to run the pump so I fixed the crack. Monday a crane will be putting 300 ft of 4 inch sch40 on the roof of another plant for us to run new glycol lines, all in megapress thankfully.

LuketheDog

Well-known member

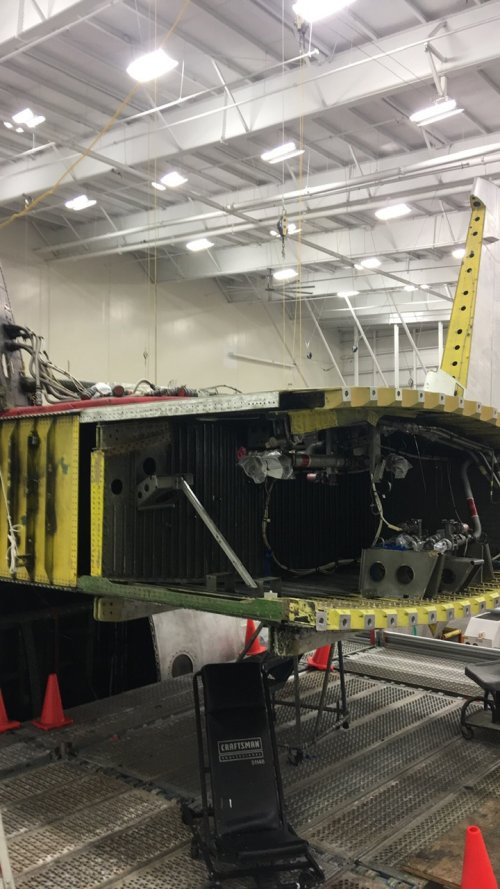

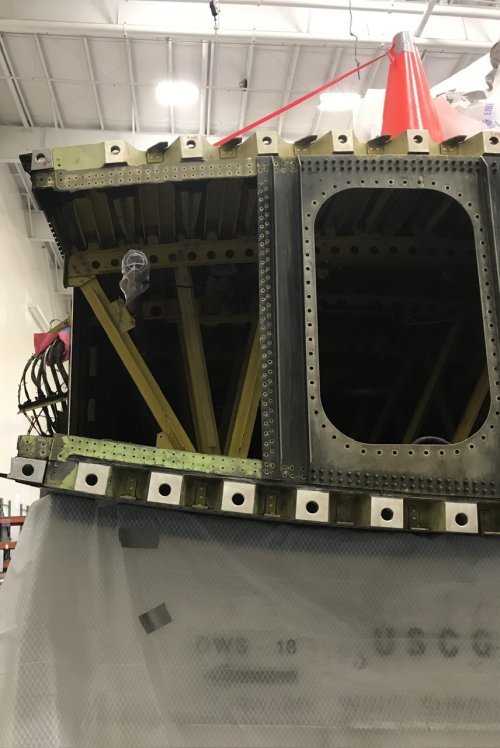

This is from a while ago, was part of a wing there that we tore apart to rebuild.

View attachment 311436

Different plane but tore this one apart just to replace one piece.

View attachment 311438

View attachment 311439

View attachment 311440

View attachment 311441

A wing from what? That thing is big!

np307

Well-known member

Been a wild week over here. This tanker is what happens when a positive displacement pump starts moving milk and the hatch on the tank isn't vented. Those big pd pumps just do not care what's happening, as long as there's liquid they are going to move it. Sucked a vacuum and collapsed the tank.

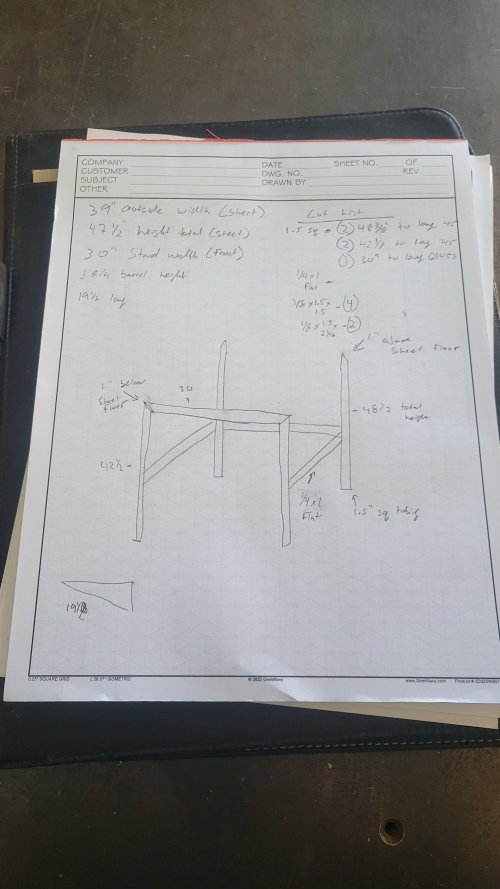

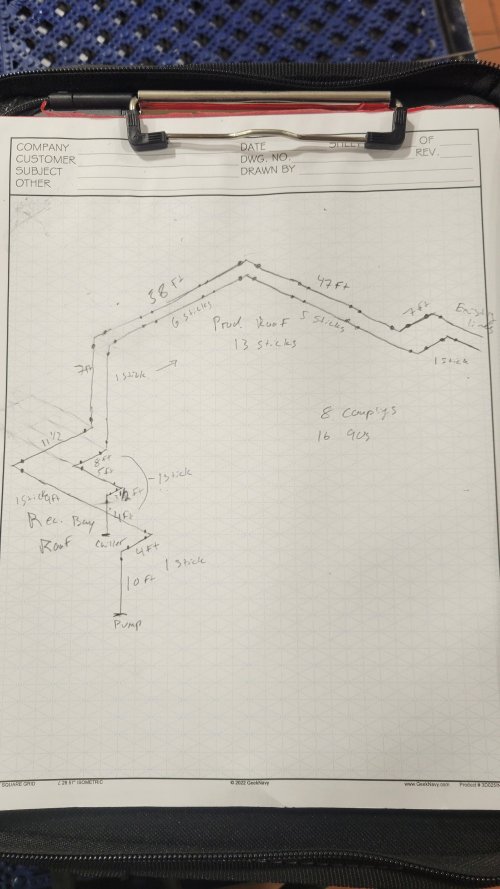

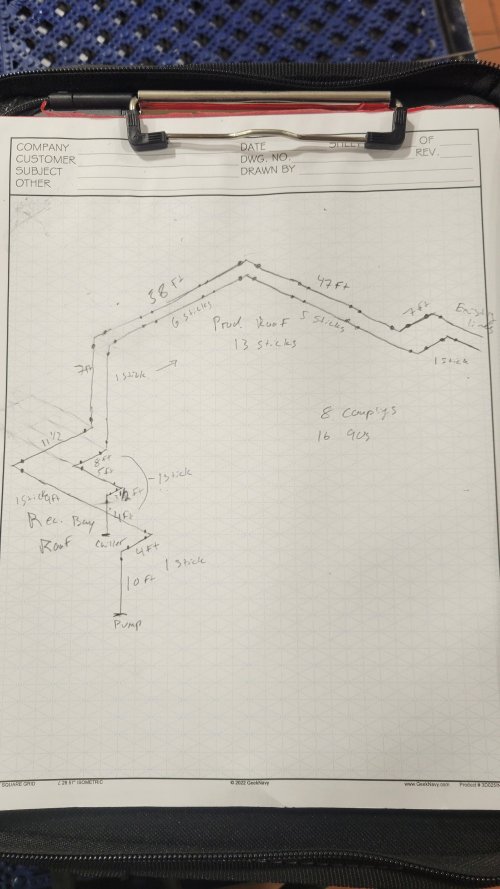

Then at another plant we started a huge piping job that we are doing in megapress. 4 inch pipe, all pressed fittings except for a couple specialty connections. Just a picture of my rough print for now.

And we've got a helper now. Not sure if he will stick around but it's nice to have another set of hands to do stuff while I'm welding.

Then at another plant we started a huge piping job that we are doing in megapress. 4 inch pipe, all pressed fittings except for a couple specialty connections. Just a picture of my rough print for now.

And we've got a helper now. Not sure if he will stick around but it's nice to have another set of hands to do stuff while I'm welding.

Goodfish

Well-known member

OK my metalworking friends—here is the challenge. I have about 1500 one eighth inch holes to drill horizontally into stainless steel sheet metal. It’s wearing my guys out not to mention drill bits. Does anybody here have any tips for the best bits and techniques for light gage SS drilling as well as has anyone seen anything like a horizontal drill press? Mag drill won’t work because it is stainless and also the surface where we are drilling is recessed so a vacuum attachment won’t work. Thanks!

Redmt

Well-known member

Cobalt or carbide drill bits and tell the guys their lucky to have a job.

I like to use Terry bits on a chucking spud drilling 301 and 321 stainless paired with a 20v battery drill.OK my metalworking friends—here is the challenge. I have about 1500 one eighth inch holes to drill horizontally into stainless steel sheet metal. It’s wearing my guys out not to mention drill bits. Does anybody here have any tips for the best bits and techniques for light gage SS drilling as well as has anyone seen anything like a horizontal drill press? Mag drill won’t work because it is stainless and also the surface where we are drilling is recessed so a vacuum attachment won’t work. Thanks!

I have used a ton of cobalt bits on it too, high speed stainless bits suck and hate using them.

What kind of stainless? 301 full hard drills better since it will move material out whereas when I drill 301 1/4 hard it wants to be "gummy" and push metal and make burs more than cut material out of the way.

Working on airplanes I have very tight tolerances on holes and usually start small with a #40 hole(3/32) and then use dual marginal drill bits to step up to a #30 hole(1/8) to create a cleaner hole, if they go to 3/16 then I use reamers for the close tolerance.

Reference #40 is 0.098" compared to 3/32 at 0.0938" and #30 is .1285" compared to 1/8 at .125"

The threaded 1/8 Terry bit

Chucking spud

Dual marginal step bit

Piloted Double Margin Drills

Designed for close tolerance drilling in titanium, stainless, heat treated material and aluminum alloys. When the drill point penetrates enough for the second margin to contact the wall of the hole, the point is stabilized and true cylindrical geometry is established. Smooth accurate holes are...

Also have seen the machinist use started bits to poke holes, not what they are designed for but if it works it works.

McMaster-Carr

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

Last edited:

trackerbacker

Well-known member

- Joined

- Jun 30, 2023

- Messages

- 453

4) goals. I enjoy welding, but I also am a pastor at heart. We are working on planting a church and while there'll still be plenty of years I'll have to work bivocationally, ultimately I don't plan to be doing it foforever.

If this has been touched on, excuse me.

But the conviction in this statement, tells me this should be #1 for you, not #4. Moot point yes, but clearly this is where your heart and mind is, and that alone is enough to warrant for it to always be stated first and foremost with that conviction, not fall be the wayside as a tertiary reason.

Good on you, and best of luck in your chosen endeavor.

Similar threads

- Replies

- 2

- Views

- 579

- Replies

- 37

- Views

- 3K

- Replies

- 7

- Views

- 1K