Addicting

Well-known member

I have been loading up some Accubonds seconds from SPS and have been noticing a decent variance in bullet OAL and Ogive of a couple hundred thousands. How much does that really matter in a sub 500 yard light hunting rifle?

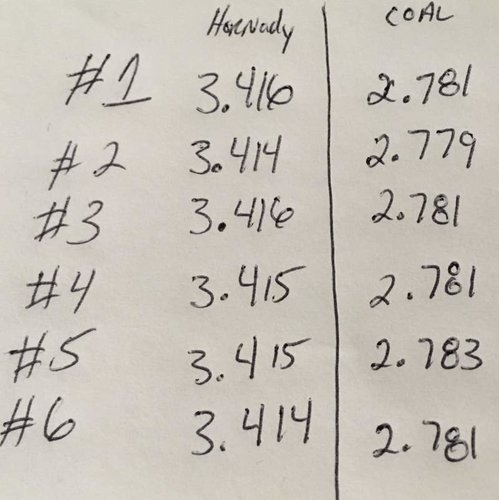

I am not an F class shooter but want to have the best consistency I can. I set my RCBS reloading die and lock it in, I would like to see them coming out the same. When I do OAL I get 2.722 to 2.727 with a couple of climbing to 2.730 (.070 jump off the lands). I though it may of just been the plastic tips or the way I positioned it. So, I bought a Hornady set up to measure my Ogive, what I am finding out is that I still have the same issue, its just easier to measure. Now with the added length of the device and measured to the Ogive I am getting 3.443, 3.440, 3.442, 3.438. (just off the lands it should be 3.440)

Do you guys measure and sort all of your bullets to get the most consistency?

What spread is acceptable, +/- .005 spread?

Do you chase the Ogive seating by changing you die cannula?

Has any one tested Accubond 1sts to see if they are more consistent in Ogive/weight than the 2nds? I know the bullets say cosmetic but Nosler weight sorts as well.

Thanks Tony

I am not an F class shooter but want to have the best consistency I can. I set my RCBS reloading die and lock it in, I would like to see them coming out the same. When I do OAL I get 2.722 to 2.727 with a couple of climbing to 2.730 (.070 jump off the lands). I though it may of just been the plastic tips or the way I positioned it. So, I bought a Hornady set up to measure my Ogive, what I am finding out is that I still have the same issue, its just easier to measure. Now with the added length of the device and measured to the Ogive I am getting 3.443, 3.440, 3.442, 3.438. (just off the lands it should be 3.440)

Do you guys measure and sort all of your bullets to get the most consistency?

What spread is acceptable, +/- .005 spread?

Do you chase the Ogive seating by changing you die cannula?

Has any one tested Accubond 1sts to see if they are more consistent in Ogive/weight than the 2nds? I know the bullets say cosmetic but Nosler weight sorts as well.

Thanks Tony